- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 18 Author: Xicheng EP LTD Publish Time: 2023-04-20 Origin: Xicheng EP LTD

Wet scrubbers are air pollution control devices that use a liquid, usually water, to remove pollutants from industrial air streams. The process involves a series of steps:

Inlet Duct: Contaminated gas stream is directed into the inlet duct of the wet scrubber.

Contact with liquid: The gas flow then comes into contact with liquid (water or other solvent) in the wash chamber. Liquids can be sprayed into the air stream or layered along the fill material to increase the contact surface area.

Absorption: Contaminants in the air stream are absorbed by the liquid. This occurs through a combination of physical and chemical processes, such as absorption, adsorption and reactions.

Separation: The now clean gas stream is separated from the liquid by a demister or demister pad. This prevents liquid from escaping with the airflow.

Discharge: The cleaned gas stream exits the scrubber through the outlet duct.

Liquid Waste Disposal: Liquid waste is collected in sumps or tanks and treated or disposed of in accordance with environmental regulations.

Wet scrubbers can be used to remove a wide variety of pollutants, including particulate matter, sulfur dioxide, nitrogen oxides, volatile organic compounds and hazardous air pollutants. The effectiveness of a wet scrubber depends on factors such as gas flow rate, liquid flow rate, contact time and the chemical nature of the contaminant.

Wet scrubber, also known as a gas scrubber system, spray tower, packed tower, is an air pollution control device that removes pollutants by using liquids to capture and remove them from industrial exhaust air.

The basic operation of a wet scrubber involves directing an exhaust stream through a scrubbing solution, usually water, that contains chemicals or reagents that react with pollutants to form compounds that are more easily removed. The solution can be sprayed, atomized or submerged on packaging material or scrubbing surfaces, which increases the contact surface area between gas and liquid.

The scrubbed gas then passes through a demister to remove any remaining liquid droplets before being discharged to the atmosphere. Wet scrubbers are commonly used in various industries such as chemical, pharmaceutical, metal processing and power generation to control emissions of particulate matter, sulfur dioxide, nitrogen oxides and other harmful pollutants.

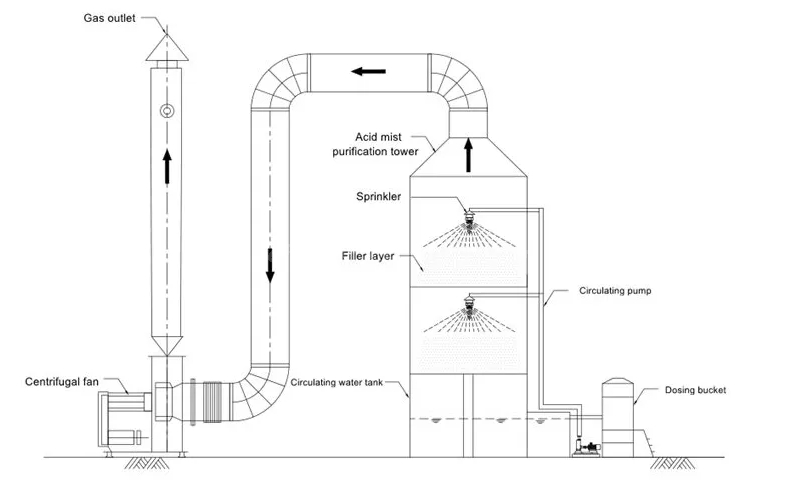

Wet scrubber is an air pollution control device that removes pollutants from an exhaust stream by scrubbing the gas with a liquid, usually water. The structure of a wet scrubber usually consists of the following components:

Inlet Duct: This is where the polluted gas enters the scrubber.

Washing chamber: The washing chamber is where the gas comes into contact with the washing liquid. The chamber can be designed in various shapes, such as cylindrical or rectangular, to maximize the contact between gas and liquid.

Water tank: used to store the water and washing liquid needed in the washing process.

Water Spray Systems: These are located in the wash compartment and are used to spray wash liquid onto the air flow.

Scrubber packing: multi-faceted spherical packing is used to increase the contact area of gas and liquid to improve processing efficiency. The more packing layers, the higher the processing efficiency.

Transparent window: for daily inspection and maintenance.

Demister layer: Demister layer is used to remove liquid that may be entrained in the airflow.

Automatic dosing system: The system passes real-time detection of the water tank.

Outlet piping: The cleaned gas leaves the scrubber through the outlet piping.

They are frequently used in industries such as power generation, metal processing, chemical production, and cement manufacturing, among others.

Some specific applications where wet scrubbers are commonly used include:

Removing sulfur dioxide (SO2) from flue gas emissions at coal-fired power plants.

Controlling emissions of volatile organic compounds (VOCs) from paint and coating operations.

Capturing particulate matter (PM) and heavy metals from metal processing operations.

Controlling acid gases such as hydrogen chloride (HCl) and hydrogen fluoride (HF) in chemical production facilities.

Reducing odors and emissions from wastewater treatment plants.

Gas flow is counter-current to the liquid flow.

Smaller footprint required at the expense of increased height requirements.

Generally, less costly from both capital and operational perspectives.

Scrubber vessel is round (generally).

Crossflow/Horizontal Flow:

Gas flow is cross-current (perpendicular) to the liquid flow.

Sacrifices footprint for height.

Slightly less efficient due to cross-current flow, although this disadvantage is minimized when treating the more water-soluble acids (e.g. H2SO4, HCl).

Scrubber vessel is rectangular

The materials used to make wet scrubbers depend on the specific application and the type of contaminants to be removed.

However, some common materials used to make wet scrubbers include:

PP (polypropylene): PP is a lightweight and economical plastic material that can be used for waste gas treatment with high corrosion resistance, because polypropylene has good corrosion resistance, light material, easy installation and strong durable. Compared with wet scrubbers made of other materials, the production cost is lower and it is widely recommended.

Stainless Steel: This is a commonly used material in wet scrubbers due to its corrosion resistance and high durability.

Fiberglass Reinforced Plastic (FRP): This material is lightweight, strong and highly corrosion resistant, making it an excellent choice for wet scrubber construction.

High Density Polyethylene (HDPE): HDPE is a thermoplastic material with high chemical and high temperature resistance, making it ideal for use in corrosive environments.

Carbon Steel: This material is commonly used in wet scrubbers for its strength and durability, but may require a protective coating to prevent corrosion.

The specific materials used in a wet scrubber depend on factors such as the type and concentration of contaminants to be removed, operating temperature and pressure, and the general requirements of the industrial process.

Some advantages and disadvantages of wet scrubbers are:

Advantages

Highly effective: Wet scrubbers can remove a wide range of pollutants, including particulate matter, sulfur dioxide, nitrogen oxides, and volatile organic compounds.

Versatility: Wet scrubbers can be used in a variety of industries, including chemical processing, metal finishing, and power generation.

Easy to operate: Wet scrubbers are generally simple to operate and maintain, and require minimal training.

Can recover valuable materials: In some cases, wet scrubbers can be used to recover valuable materials from exhaust streams, such as sulfuric acid in the production of fertilizers.

Disadvantages

High initial cost: Wet scrubbers can be expensive to install, especially for large exhaust streams.

High energy consumption: Wet scrubbers require a significant amount of energy to operate, particularly for the recirculation of the liquid.

Water consumption: Wet scrubbers require large amounts of water to operate, which can be a concern in areas where water is scarce.

Disposal of waste: Wet scrubbers produce a liquid waste stream that must be treated and disposed of properly, which can be expensive and time-consuming.

Maintenance requirements: Wet scrubbers require regular maintenance, including the replacement of nozzles, pumps, and other components, which can be costly.

Designing a wet scrubber is a very important link, which determines the size and overall structure of the scrubber, which will ultimately affect the operating efficiency of the scrubber. Designing a wet scrubber involves several steps, including determining gas flow, contaminant concentration, scrubbing fluid flow, scrubber size, and fan requirements. The following is the general procedure for designing a wet scrubber:

1. Determine gas flow: This can be determined from a process flow diagram or measured using a flow meter.

2. Determining Pollutant Concentration: The concentration of pollutants in the gas stream is important in determining scrubber efficiency. This can be measured using a gas analyzer or obtained from process data.

3. Selecting a Washing Solution: The choice of washing solution depends on the contaminants to be removed. For example, water is commonly used to remove acid gases, while caustic solutions are used to remove ammonia and sulfur dioxide.

4. Determine scrubbing liquid flow: This can be calculated using the gas flow and the liquid to gas ratio (L/G). L/G ratio depends on scrubber type and design.

5. Scrubber sizing: Scrubber sizing depends on gas flow rate, contaminant concentration, and scrubber flow rate. Scrubber diameter is generally based on gas velocity and residence time. Height is determined by scrubber pressure drop and desired scrubber efficiency.

6. Selecting a Fan: Fan size depends on scrubber pressure drop, gas flow rate, and scrubber size.

7. Calculate the pressure drop: The pressure drop is the pressure difference between the scrubber inlet and outlet. This can be calculated using gas velocity, scrubber diameter and scrubber height.

8. Calculating Scrubber Efficiency: Scrubber efficiency is the percentage of pollutants removed by the scrubber. This can be calculated using the pollutant concentrations before and after the scrubber.

9. Validate the design: Once the design is complete, it should be validated by field testing the scrubber performance. This can be done using gas analyzers and flow meters to measure inlet and outlet gas concentrations and flow rates.

Note that design procedures may vary depending on the specific scrubber type and application. It is recommended to consult a professional engineer for the design of a wet scrubber.

The treatment efficiency of a wet scrubber can vary depending on several factors such as the type of pollutants being removed, the design and operating conditions of the scrubber, and the effectiveness of maintenance and operation.

In general, wet scrubbers are effective at removing particulate matter, sulfur dioxide (SO2), and some other acid gases such as hydrogen chloride (HCl) and hydrogen fluoride (HF). They can also be effective at removing some volatile organic compounds (VOCs) and nitrogen oxides (NOx), although their efficiency for these pollutants can vary.

The overall treatment efficiency of a wet scrubber is typically expressed as a percentage of the pollutant removed from the gas stream. For example, a scrubber with an efficiency of 90% for SO2 would remove 90% of the SO2 from the gas stream.

It's important to note that the treatment efficiency of a wet scrubber can be affected by several factors such as the pH of the scrubbing solution, the temperature and humidity of the gas stream, and the design and operation of the scrubber. Proper maintenance and operation of the scrubber are also essential to ensure optimal treatment efficiency over time.

The exhaust gas treatment system generally consists of a wet scrubber, a ventilation duct, an activated carbon box, an automatic dosing system, a fan, and a combination of other equipment. In response to different needs, different equipment can be added to improve the efficiency of exhaust gas purification.

Common other related equipment:

FAQ

Q:How we choose packing type ?(From YouTube)

A: There are many types of packing types, including PP plastic material, metal material and ceramic material. They are respectively suitable for different working temperatures and corrosive environments. It is necessary to choose the appropriate packing type according to the specific gas corrosion and temperature.

Q:What is the difference between a wet scrubber and a dry scrubber?(From Quora)

A: A wet scrubber, also known as a wet scrubber system or wet scrubbing system, is a device that uses water or other liquids to remove contaminants from an air stream. The gas is passed through a liquid (usually water), which captures the contaminants and removes them from the gas.

Dry scrubbers, also known as dry scrubber systems or dry scrubbing systems, use dry adsorbent materials such as activated carbon or sodium bicarbonate to remove contaminants from air streams.

Q:Can a wet scrubber remove CO2?(From Quora)

A:Wet scrubber cannot be used to remove carbon dioxide, and the spray scrubber is mainly used to remove harmful exhaust gases, such as sulfur dioxide, ammonia, hydrogen sulfide and other exhaust gases that can be dissolved in water. The harmful components are removed through the adsorption reaction of the scrubber to meet the discharge standard.

If you are interested in knowing more about wet air scrubbers, please contact Xicheng EP LTD. At XICHENG EP, we design state-of-the-art odor and emission control systems for specific industry applications. We use a variety of construction materials, dimensions and other elements to create the most efficient solution.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |