- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 18 Author: China xicheng Publish Time: 2021-04-16 Origin: China xicheng

The production process of electronic products involves painting, baking, and other functions. The paint and other coatings used in these processes require many organic substances such as toluene, xylene, ethylbenzene, etc., as solvents, and these organic substances cannot be attached to the product during the spraying process. But in spraying, as the paint is consumed, it will gradually volatilize and form organic waste gas. On the one hand, these organic waste gas can form photochemical smog and destroy the ozone layer. It destroys atmospheric balance and poses a threat to the environment. On the other hand, these organic waste gas can cause chronic human poisoning, damage the liver system, and may cause endocrine disorders, etc., which are serious harms. Healthy body.

I combined traditional organic waste gas treatment methods, focusing on the plant equipment, production conditions, and technological process of electronics companies, combined with the characteristics of waste gas generated during the spraying process, low concentration, and large air volume. A set of comprehensive treatment projects was scientifically and rationally designed: adsorption treatment-desorption regeneration-combustion release.

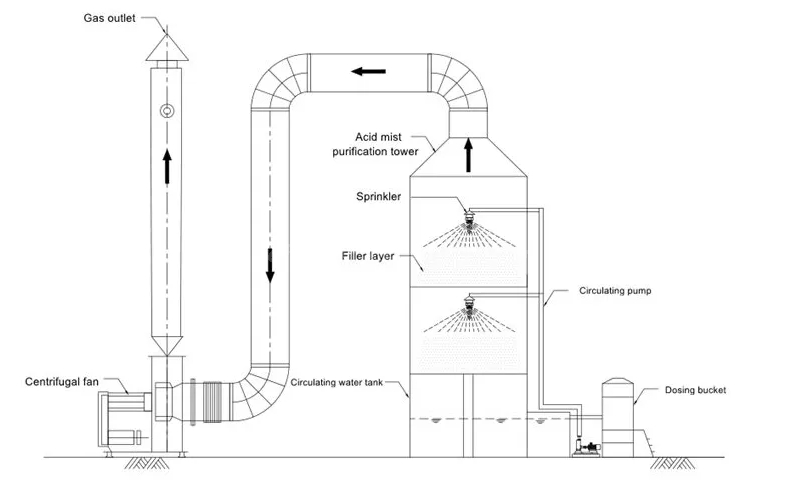

After the electronic product spraying process is completed, the organic waste gas produced is mixed with fine particles and a paint mist. If this delicate particulate matter and paint mist enter the activated carbon adsorption chamber together with the organic waste gas, the active sites for the activated carbon to adsorb the organic waste gas will be significantly reduced, and the adsorption efficiency will be reduced. Therefore, before the exhaust gas enters the adsorption chamber, it needs to enter the spray scrubber to remove fine particles and paint mist through washing.

1. The exhaust gas generated in the spraying process is treated by adsorption, desorption, regeneration, combustion and release, and a complete set of comprehensive treatments.

2. The sprayed waste first passes through the spray scrubber, which is composed of multiple perforated fiber layers. The number of holes per unit area of each layer increases from the first layer. When the exhaust gas passes through the scrubber, the fine particles, paint mist, and a small part of organic matter in the exhaust gas continue to collide with the micropores and bond.

3. The organic waste gas purified from the spray scrubber enters the adsorption chamber. The activated carbon used in the adsorption chamber is not ordinary activated carbon but a new type of activated carbon with dense honeycomb pores. This activated carbon has a larger surface area and, thus, more active adsorption sites. When the low-concentration organic waste gas passes through the activated carbon in large quantities, toluene, xylene, and ethylbenzene are gradually absorbed by the activated carbon. The remaining dry and clean others are directly discharged. After the activated carbon active sites in the adsorption chamber are all occupied by organic waste, the activated carbon reaches a saturated state. It needs to be desorbed so that the activated carbon can be reused.

4. After the association of activated carbon and organic matter is desorbed, the activated carbon is regenerated back to the adsorption chamber and continues to adsorb the organic waste gas transported into the adsorption chamber, and the organic matter is continued to be transported to the combustion chamber. Multi-layer catalytic combustion beds are arranged in the combustion chamber, and the catalysts in these catalytic combustion beds are made of precious metals such as Pd (palladium). This kind of metal is widely used in the production process of electronic products, the reason why this kind of metal is used as a catalyst. It is easy to obtain on the production line of the electronics factory, which also makes full use of the existing resources in the factory and reduces the cost.

5. The organic waste gas undergoes a catalytic combustion reaction on the multi-layer catalytic bed. The exhaust gas is wholly burned to produce environmentally sound carbon dioxide and moisture, and waste heat is generated. The waste heat generated by the catalytic reaction is recycled to the desorption chamber to be reused and used for desorption and regeneration of activated carbon, which can be reasonably utilized. The final CO2 and H2O are directly discharged. The comprehensive treatment project design of the entire spraying waste gas considers the electronics company's production characteristics and the features of the waste gas. Combining the actual production situation and technological process of the electronics factory, making full use of the existing resources of the electronics factory, and the whole process is interlocked, which can treat exhaust gas efficiently and make full use of waste heat in the process Practical engineering design.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |