- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Material: | |

|---|---|

| Size: | |

| Availability: | |

| Quantity: | |

XC-3

Xicheng

3926909090

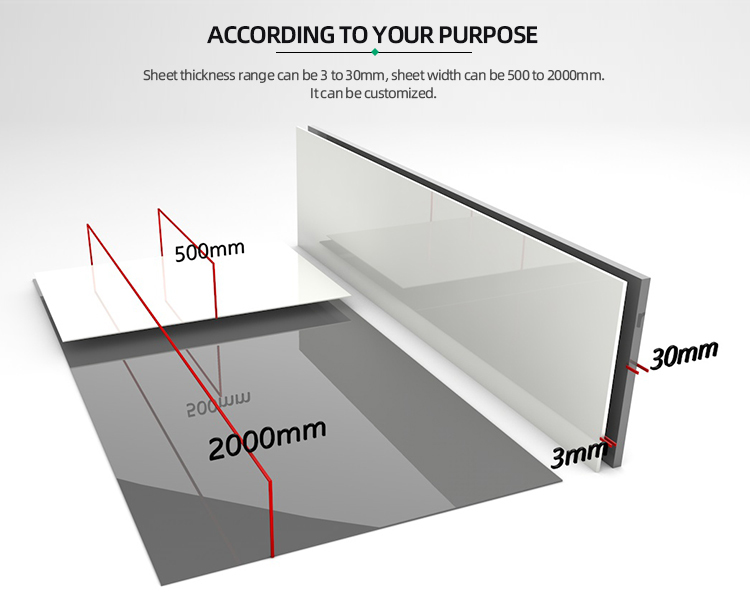

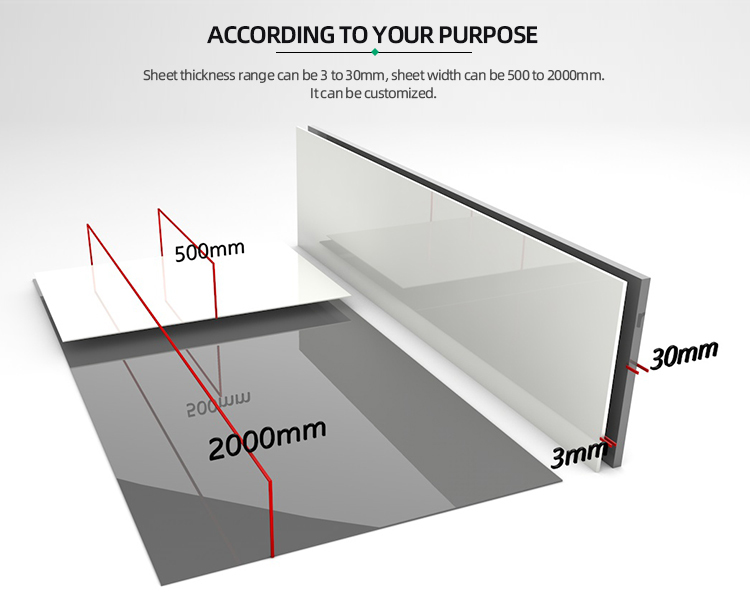

Polypropylene PP plastic sheet 15mm thick is easy to weld and process, has excellent chemical resistance, heat resistance and impact resistance, non-toxic, and odorless. It is currently one of the most environmentally friendly engineering plastics. Performance; glass fiber reinforced PP board (FRPP board): After 20% is reinforced by glass fiber, in addition to maintaining the original excellent performance, the strength and rigidity are doubled compared to PP, and it has good heat resistance, low temperature Impact resistance, corrosion resistance and arc resistance, low shrinkage. Especially suitable for chemical fiber, chlor-alkali, petroleum, dyes, pesticides, food, medicine, light industry, metallurgy, sewage treatment and other fields.

Since homopolymer PP is very brittle when the temperature is higher than 0°C, many commercial PP materials are random copolymers with 1 to 4% ethylene or clamp copolymers with higher ethylene content. Copolymer PP material has lower thermal distortion temperature (100°C), low transparency, low gloss, low rigidity, but has stronger impact strength. The strength of PP increases with the increase of ethylene content. The Vicat softening temperature of PP is 150°C. Due to the high crystallinity, the surface rigidity and scratch resistance of this material are very good. PP does not have the problem of environmental stress cracking. Usually, the PP is modified by adding glass fiber, metal additives or thermoplastic rubber. The flow rate MFR of PP ranges from 1 to 40. PP materials with low MFR have better impact resistance but lower elongation strength.

For materials with the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Due to crystallization, the shrinkage rate of PP is quite high, generally 1.8~2.5%. And the direction uniformity of shrinkage rate is much better than that of PE-HD and other materials. Adding 30% of glass additives can reduce the shrinkage rate to 0.7%. Both homopolymer and copolymer PP materials have excellent moisture absorption, acid and alkali corrosion resistance, and solubility resistance. However, it has no resistance to aromatic hydrocarbon (such as benzene) solvents, chlorinated hydrocarbon (carbon tetrachloride) solvents, etc. PP does not have oxidation resistance at high temperatures like PE.

Chemical stability: The white polypropylene sheet has excellent chemical stability and can resist the erosion and corrosion of many chemical substances. This makes it ideal for use in corrosive environments.

Weather resistance: The white polypropylene sheet can maintain its appearance and performance for a long time in the outdoor environment, and is not easily affected by factors such as ultraviolet radiation, high temperature, and humidity.

Low water absorption: Polypropylene has low water absorption, so it is not easy to get wet and lose its performance after getting wet. This makes it stable in wet environments.

Lightweight: White polypropylene sheet is a lightweight material that is easy to handle, install and process. This is especially beneficial for projects requiring large area applications.

Electrical Insulation: Polypropylene is an excellent electrical insulator and does not conduct electricity. Therefore, it is widely used in the fields of electronics, electrical appliances and communications.

Machinability: White polypropylene sheets are easy to cut, drill, weld and bend, and can be custom machined as required to make them suitable for a variety of applications.

Hygienic Approval: Polypropylene material is widely used in medical devices, food packaging and pharmaceuticals because of its good hygienic approval and easy cleaning and disinfection.

Environmentally friendly: Polypropylene is a recyclable plastic that can be recycled at the end of its life, helping to reduce waste.

Cost-Effective: White polypropylene sheets are relatively economical and cost less, thus providing cost-effectiveness in a variety of projects.

Impact resistance: Polypropylene board has certain impact resistance and is suitable for scenes that need to resist mechanical impact or impact.

It should be noted that although the white polypropylene board has many advantages, it also has some limitations, such as its poor thermal stability in high temperature environments, and thermal deformation may occur. When selecting materials, various factors should be considered comprehensively according to specific application requirements.

Polypropylene PP plastic sheet 15mm thick is easy to weld and process, has excellent chemical resistance, heat resistance and impact resistance, non-toxic, and odorless. It is currently one of the most environmentally friendly engineering plastics. Performance; glass fiber reinforced PP board (FRPP board): After 20% is reinforced by glass fiber, in addition to maintaining the original excellent performance, the strength and rigidity are doubled compared to PP, and it has good heat resistance, low temperature Impact resistance, corrosion resistance and arc resistance, low shrinkage. Especially suitable for chemical fiber, chlor-alkali, petroleum, dyes, pesticides, food, medicine, light industry, metallurgy, sewage treatment and other fields.

Since homopolymer PP is very brittle when the temperature is higher than 0°C, many commercial PP materials are random copolymers with 1 to 4% ethylene or clamp copolymers with higher ethylene content. Copolymer PP material has lower thermal distortion temperature (100°C), low transparency, low gloss, low rigidity, but has stronger impact strength. The strength of PP increases with the increase of ethylene content. The Vicat softening temperature of PP is 150°C. Due to the high crystallinity, the surface rigidity and scratch resistance of this material are very good. PP does not have the problem of environmental stress cracking. Usually, the PP is modified by adding glass fiber, metal additives or thermoplastic rubber. The flow rate MFR of PP ranges from 1 to 40. PP materials with low MFR have better impact resistance but lower elongation strength.

For materials with the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Due to crystallization, the shrinkage rate of PP is quite high, generally 1.8~2.5%. And the direction uniformity of shrinkage rate is much better than that of PE-HD and other materials. Adding 30% of glass additives can reduce the shrinkage rate to 0.7%. Both homopolymer and copolymer PP materials have excellent moisture absorption, acid and alkali corrosion resistance, and solubility resistance. However, it has no resistance to aromatic hydrocarbon (such as benzene) solvents, chlorinated hydrocarbon (carbon tetrachloride) solvents, etc. PP does not have oxidation resistance at high temperatures like PE.

Chemical stability: The white polypropylene sheet has excellent chemical stability and can resist the erosion and corrosion of many chemical substances. This makes it ideal for use in corrosive environments.

Weather resistance: The white polypropylene sheet can maintain its appearance and performance for a long time in the outdoor environment, and is not easily affected by factors such as ultraviolet radiation, high temperature, and humidity.

Low water absorption: Polypropylene has low water absorption, so it is not easy to get wet and lose its performance after getting wet. This makes it stable in wet environments.

Lightweight: White polypropylene sheet is a lightweight material that is easy to handle, install and process. This is especially beneficial for projects requiring large area applications.

Electrical Insulation: Polypropylene is an excellent electrical insulator and does not conduct electricity. Therefore, it is widely used in the fields of electronics, electrical appliances and communications.

Machinability: White polypropylene sheets are easy to cut, drill, weld and bend, and can be custom machined as required to make them suitable for a variety of applications.

Hygienic Approval: Polypropylene material is widely used in medical devices, food packaging and pharmaceuticals because of its good hygienic approval and easy cleaning and disinfection.

Environmentally friendly: Polypropylene is a recyclable plastic that can be recycled at the end of its life, helping to reduce waste.

Cost-Effective: White polypropylene sheets are relatively economical and cost less, thus providing cost-effectiveness in a variety of projects.

Impact resistance: Polypropylene board has certain impact resistance and is suitable for scenes that need to resist mechanical impact or impact.

It should be noted that although the white polypropylene board has many advantages, it also has some limitations, such as its poor thermal stability in high temperature environments, and thermal deformation may occur. When selecting materials, various factors should be considered comprehensively according to specific application requirements.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |