- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 18 Author: Xicheng Ep Ltd Publish Time: 2021-09-27 Origin: Xicheng Ep Ltd

Exhaust gas introduction: The company will volatilize a certain amount of acid and alkali waste gas during the production process. The main pollutants of acid and alkali waste gas are nitric acid mist, hydrogen chloride, sulfuric acid mist, cyanide, chromic acid mist, and alkali mist.

Acid-base waste gas is generally flammable, explosive, toxic and harmful, insoluble in water, soluble in organic solvents, and difficult to handle. Domestic acid-base waste gas treatment generally adopts the acid-base neutralization method.

Main components: sulfur oxides, nitrogen oxides, carbon oxides, halogens and their compounds, etc. Such as hydrochloric acid (HCl), hydrogen fluoride gas (HF), ammonia (NH3), sulfuric acid mist (H2SO4), chromic acid mist (CrO3) ), hydrocyanic acid gas (HCN), alkali vapor (NaOH), hydrogen sulfide gas (H2S), formalin (HCHO) and other water-soluble gases.

Main sources: PCBs, semiconductors, electronics and optoelectronics, metallurgical plants, plastics, pickling and electroplating plants, chemicals, electrolysis, battery electroplating, pharmaceuticals, deodorization and other water-soluble air pollutants that produce waste gas production and processing enterprises.

Main hazards: The main pollutants that cause atmospheric acidification are sulfur dioxide and nitrogen oxides emitted during the combustion of fossil fuels. The emission of acid mist cannot be ignored, because compared with the combustion gas phase, the acid mist is more corrosive and more toxic Big. For example, the toxicity of sulfuric acid mist is about 10 times that of sulfur dioxide. The discharge of acid mist will cause acid mist and acid gas to diffuse in the air of the workplace, and the discharge into the atmosphere will cause acid to deposit in the atmosphere. It not only endangers the health of workers and residents around the plant, corrodes plant equipment and instruments, causing loss of production and life, but also adversely affects the survival of crops and other animals and plants, and damages buildings. Cultural relics, etc. Damage etc.

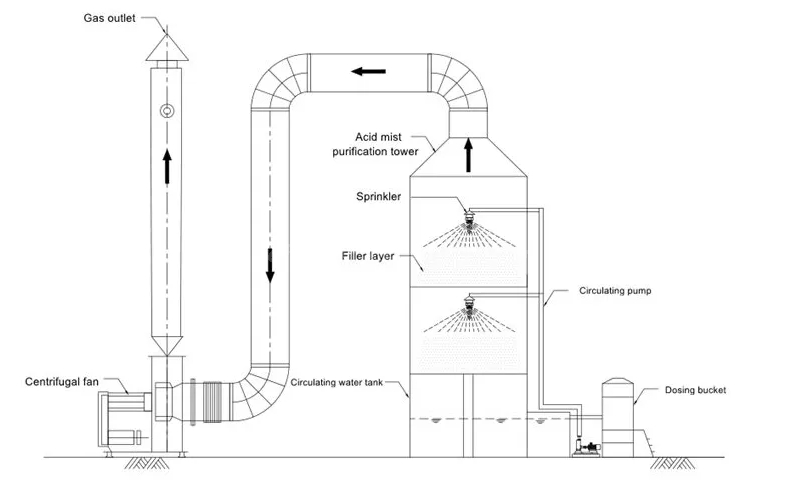

Acid-base waste gas treatment equipment is used to neutralize and remove acidic or basic pollutants from industrial exhaust gases. The working principle involves various chemical reactions that aim to convert harmful gases into less harmful or non-toxic substances. The primary components of such equipment typically include scrubbers, neutralization tanks, and monitoring systems. Here's an overview of the working principle:

Identification of Acidic or Basic Gases: The first step is to identify whether the waste gas contains acidic or basic pollutants. Common acidic gases include sulfur dioxide (SO2), hydrogen chloride (HCl), and nitrogen oxides (NOx), while ammonia (NH3) is a common basic gas.

Scrubbing: The waste gas is passed through a scrubber, which contains a liquid chemical solution. The choice of chemical solution depends on the type of pollutant to be removed. For acidic gases, an alkaline solution is used (e.g., sodium hydroxide or calcium hydroxide), while for basic gases, an acidic solution is used (e.g., sulfuric acid).

Chemical Reaction - Acid Neutralization: In the case of acidic gases, the alkaline solution in the scrubber reacts with the acidic pollutants to form neutral salts. For example, sulfur dioxide reacts with sodium hydroxide to produce sodium sulfite:

SO2 + 2NaOH → Na2SO3 + H2O

Chemical Reaction - Base Neutralization: For basic gases, the acidic solution in the scrubber reacts with the basic pollutants to form neutral salts. For instance, ammonia reacts with sulfuric acid to form ammonium sulfate:

2NH3 + H2SO4 → (NH4)2SO4

Monitoring and Control: Throughout the process, various sensors and monitoring systems are employed to ensure the efficiency and safety of the equipment. These systems continuously measure the pH levels and pollutant concentrations in the exhaust gas to adjust the chemical dosing and maintain optimal operating conditions.

Byproduct Disposal: After the chemical reactions take place, the resulting neutral salts are collected in the scrubber. The byproducts may be collected for proper disposal or further treatment, depending on their specific nature and regulations.

It's essential to note that the efficiency of acid-base waste gas treatment equipment depends on factors such as the type and concentration of pollutants, the flow rate of the exhaust gas, and the design and capacity of the treatment system. Proper maintenance and adherence to environmental regulations are crucial to ensuring the effective operation of the equipment and minimizing harmful emissions into the atmosphere.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |