- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Function: | |

|---|---|

| Availability: | |

| Quantity: | |

XC-1

Xicheng

8421399090

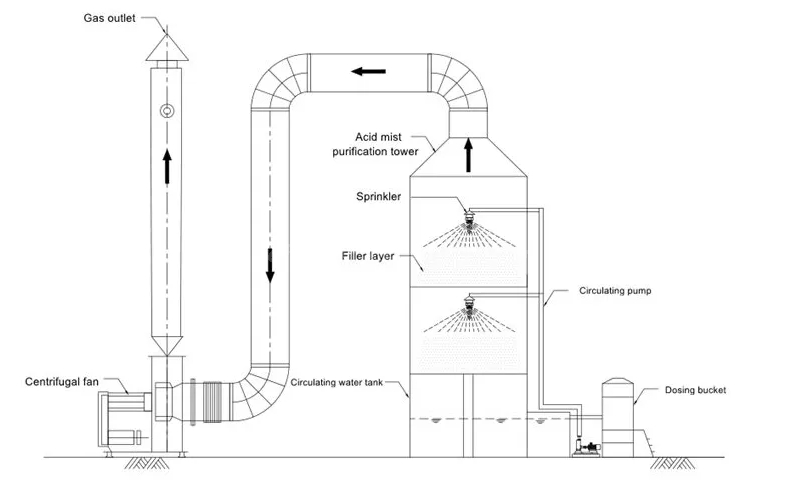

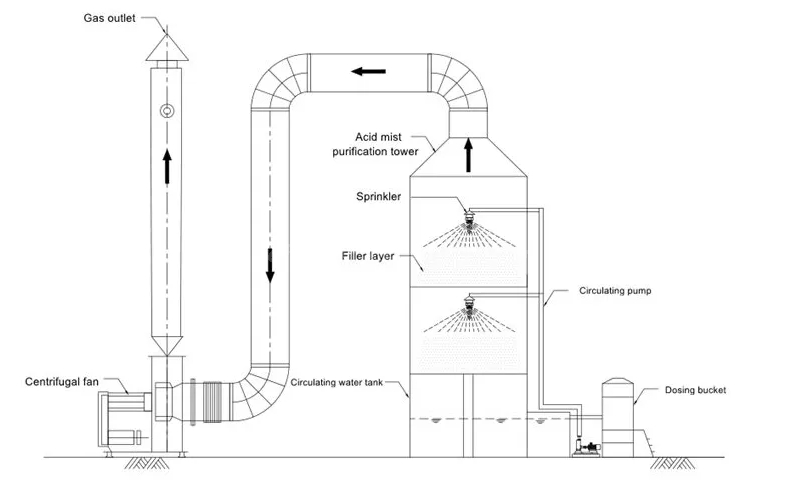

Solutions to air pollution from factories can be roughly divided into three important links. The steps are from waste gas collection, to waste gas treatment equipment and process purification, and then to the end gas detection and then to the atmosphere from the chimney.

1. Exhaust gas collection

At each pollution source point of the factory's exhaust gas emission, according to the actual production conditions of the working conditions, select the appropriate side-suction or top-suction exhaust gas suction hoods, and connect them with the air ducts one by one to form a complete exhaust gas collection system. Exhaust gas is collected under power.

Due to different waste gas treatment processes, before waste gas collection, consider whether the composition of the waste gas discharged by the factory is complex, and whether the waste gas of different natures is collected by classification, so as to facilitate the purification of the terminal waste gas to meet the standards.

2. Selection of waste gas treatment equipment and purification process

After understanding the exhaust gas composition, concentration and exhaust volume value of the factory's emission, first determine the exhaust gas treatment process, and then purchase the exhaust gas treatment equipment from the manufacturer.

In the vacant part of the factory area, the installation site is selected according to the size of the waste gas treatment system, and then the ground is leveled and cement hardened, and the equipment can be installed after entering the factory.

Or consult an environmental protection company, explain the parameters of the factory's exhaust gas, and then provide the exhaust gas treatment solution, and then purchase the corresponding exhaust gas treatment equipment from the manufacturer according to the requirements of the exhaust gas process design.

Contact the environmental protection engineering company. If the company's qualifications meet the requirements, they will install waste gas treatment equipment at the designated waste gas treatment site until the equipment is installed, and then debug and operate.

3. Exhaust emission detection

Finally, there is the exhaust gas detection link, which will affect or affect whether the exhaust gas emitted by the factory is purified, whether the gas detection at the chimney outlet meets the standard, and whether it meets the emission requirements of the national J or local environmental protection departments. Exhaust emission detection is divided into offline detection and online monitoring. Most small and medium-sized enterprises are offline monitoring. The installation requirements of online monitoring are determined by the national environmental protection department according to the nature, scale and exhaust characteristics of different industries.

Solutions to air pollution from factories can be roughly divided into three important links. The steps are from waste gas collection, to waste gas treatment equipment and process purification, and then to the end gas detection and then to the atmosphere from the chimney.

1. Exhaust gas collection

At each pollution source point of the factory's exhaust gas emission, according to the actual production conditions of the working conditions, select the appropriate side-suction or top-suction exhaust gas suction hoods, and connect them with the air ducts one by one to form a complete exhaust gas collection system. Exhaust gas is collected under power.

Due to different waste gas treatment processes, before waste gas collection, consider whether the composition of the waste gas discharged by the factory is complex, and whether the waste gas of different natures is collected by classification, so as to facilitate the purification of the terminal waste gas to meet the standards.

2. Selection of waste gas treatment equipment and purification process

After understanding the exhaust gas composition, concentration and exhaust volume value of the factory's emission, first determine the exhaust gas treatment process, and then purchase the exhaust gas treatment equipment from the manufacturer.

In the vacant part of the factory area, the installation site is selected according to the size of the waste gas treatment system, and then the ground is leveled and cement hardened, and the equipment can be installed after entering the factory.

Or consult an environmental protection company, explain the parameters of the factory's exhaust gas, and then provide the exhaust gas treatment solution, and then purchase the corresponding exhaust gas treatment equipment from the manufacturer according to the requirements of the exhaust gas process design.

Contact the environmental protection engineering company. If the company's qualifications meet the requirements, they will install waste gas treatment equipment at the designated waste gas treatment site until the equipment is installed, and then debug and operate.

3. Exhaust emission detection

Finally, there is the exhaust gas detection link, which will affect or affect whether the exhaust gas emitted by the factory is purified, whether the gas detection at the chimney outlet meets the standard, and whether it meets the emission requirements of the national J or local environmental protection departments. Exhaust emission detection is divided into offline detection and online monitoring. Most small and medium-sized enterprises are offline monitoring. The installation requirements of online monitoring are determined by the national environmental protection department according to the nature, scale and exhaust characteristics of different industries.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |