- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Function: | |

|---|---|

| Availability: | |

| Quantity: | |

XC-1

Xicheng

8421399090

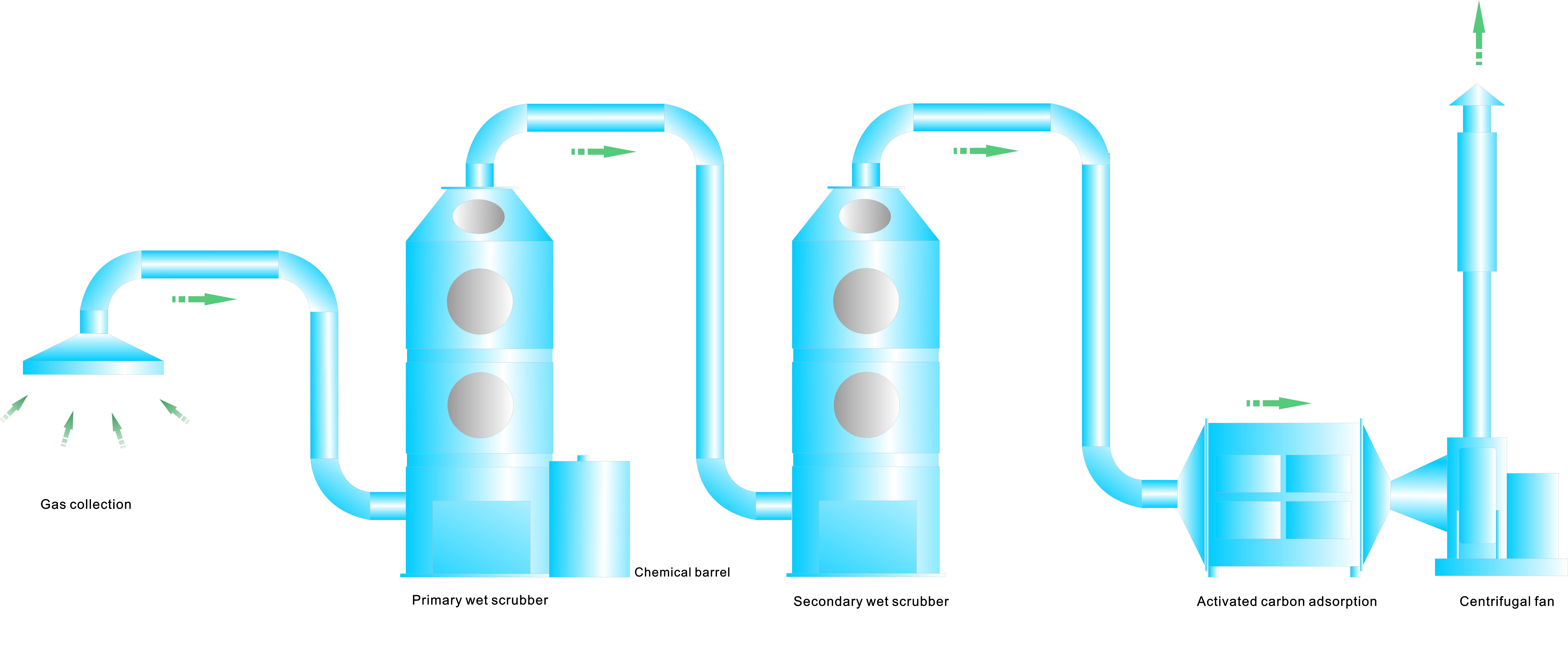

Odor control systems are widely used in wastewater treatment plants and pumping station applications where odor removal is required. These systems can be single-stage or multi-stage units using, wet scrubber, and/or carbon media technologies. The Odor Control System effectively eliminates up to 95%+ of H2S, Ammonia, Mercaptans, and many other odors.

First-stage acid scrubber absorption: Utilizing the characteristics that NH3 is very soluble in water and easy to react with acid to produce ammonium salt, 5% dilute sulfuric acid solution is used as the absorption liquid, and the waste gas is sprayed and absorbed in multiple stages to treat the waste gas. NH3. The purification efficiency is greater than 80%. Absorption with acid can greatly increase the amount of ammonia absorbed. Since the formed salt is relatively stable, the liquid after one absorption can continue to be recycled. The control of pH can ensure that the acid can fully absorb the ammonia in the exhaust gas.

Secondary chemical oxidation: adding a mixed solution of sodium hydroxide and sodium hypochlorite to the second-stage scrubber can enhance the oxidation of sodium hypochlorite and oxidize organic odorous substances such as methyl mercaptan; at the same time, a small amount of SO2 and Cl2 generated by the reaction are in the alkali Sodium salts are formed in an aggressive environment. H2S is soluble in water and easily reacts with NaOH to form Na2S. Increase the dosage of sodium hydroxide to remove H2S in the exhaust gas. The purification efficiency of hydrogen sulfide is greater than 80%.

The activated carbon bed is used for VOC organic waste gas purification treatment. The carbon bed is a dry waste gas purification equipment, which consists of a box and an activated carbon absorption unit filled in the box. Activated carbon bed is an efficient, economical and practical organic waste gas treatment equipment, which plays the role of filtering and adsorbing odor; activated carbon adsorption is widely used in the treatment of VOC organic waste gas discharged from workshops, laboratories and other environments, such as cother one, benzene, khalene, al Alkane, aldehyde, phenol, and other volatile gases are mainly used in chemical, machinery, printing, rubber, furniture, electromechanical, marine, automobile, petroleum and other industries.

The activated carbon bed treats VOC organic waste gas, with mature technology, stable operation and good treatment effect. At the same time, according to the characteristics of the exhaust gas emitted in different production processes, such as the temperature of the exhaust gas, whether it contains oil mist, dust and other related parameters, pretreatment devices such as coolers and primary filters can be built or added at the inlet end of the activated carbon bed. It protects the activated carbon absorption section and ensures that the activated ate operator carbon in be a high-efficiency state. The activated carbon absorption and absorption efficiency is high, and the purification capacity meets the national environmental protection requirements.

Custom designed to meet application requirements,

Flow ranges from 50 cfm to 500,000 cfm

Modular system

Flexible container options such as stainless steel, PP polypropylene

Single or two stage system

Vertical/horizontal design

Reduced footprint due to efficient media

Low maintenance

Rugged Design

Low life cycle cost

Energy efficient

Easy to install and operate

Optional blowe

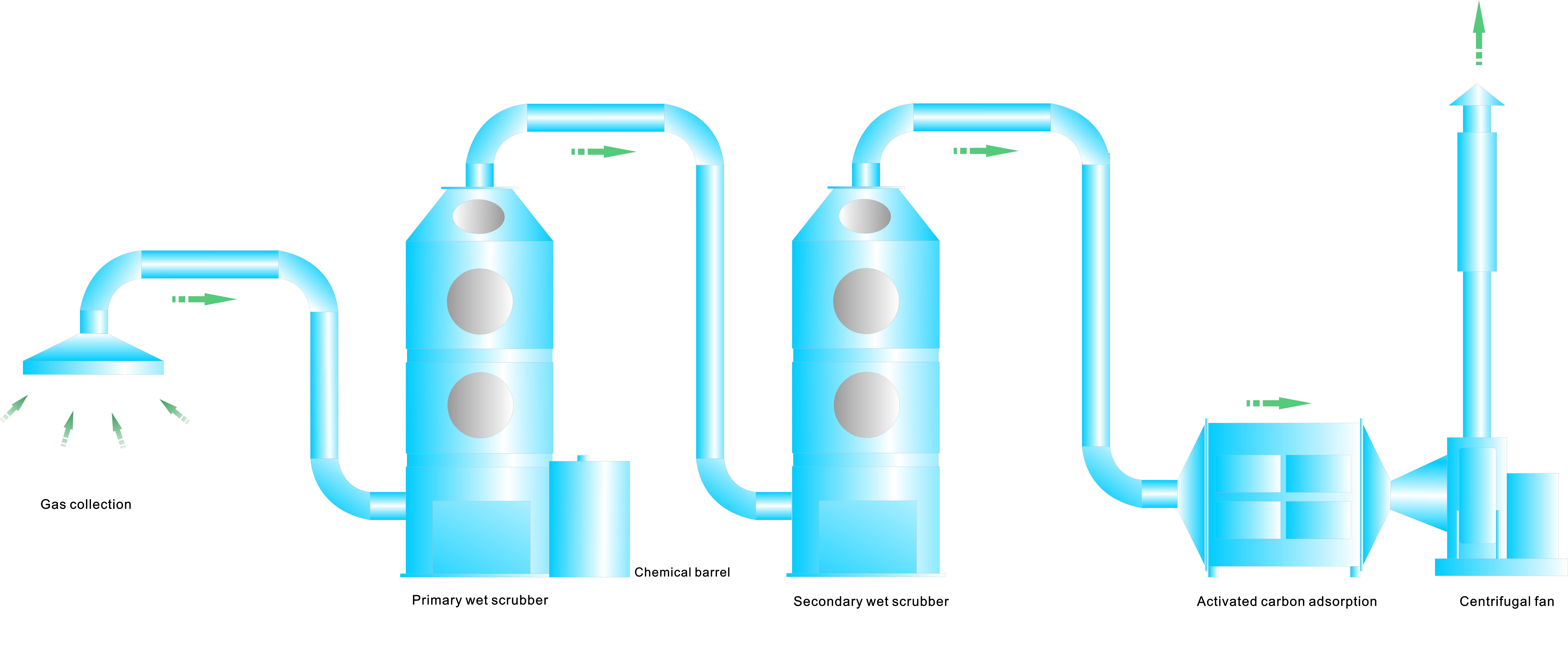

Odor control systems are widely used in wastewater treatment plants and pumping station applications where odor removal is required. These systems can be single-stage or multi-stage units using, wet scrubber, and/or carbon media technologies. The Odor Control System effectively eliminates up to 95%+ of H2S, Ammonia, Mercaptans, and many other odors.

First-stage acid scrubber absorption: Utilizing the characteristics that NH3 is very soluble in water and easy to react with acid to produce ammonium salt, 5% dilute sulfuric acid solution is used as the absorption liquid, and the waste gas is sprayed and absorbed in multiple stages to treat the waste gas. NH3. The purification efficiency is greater than 80%. Absorption with acid can greatly increase the amount of ammonia absorbed. Since the formed salt is relatively stable, the liquid after one absorption can continue to be recycled. The control of pH can ensure that the acid can fully absorb the ammonia in the exhaust gas.

Secondary chemical oxidation: adding a mixed solution of sodium hydroxide and sodium hypochlorite to the second-stage scrubber can enhance the oxidation of sodium hypochlorite and oxidize organic odorous substances such as methyl mercaptan; at the same time, a small amount of SO2 and Cl2 generated by the reaction are in the alkali Sodium salts are formed in an aggressive environment. H2S is soluble in water and easily reacts with NaOH to form Na2S. Increase the dosage of sodium hydroxide to remove H2S in the exhaust gas. The purification efficiency of hydrogen sulfide is greater than 80%.

The activated carbon bed is used for VOC organic waste gas purification treatment. The carbon bed is a dry waste gas purification equipment, which consists of a box and an activated carbon absorption unit filled in the box. Activated carbon bed is an efficient, economical and practical organic waste gas treatment equipment, which plays the role of filtering and adsorbing odor; activated carbon adsorption is widely used in the treatment of VOC organic waste gas discharged from workshops, laboratories and other environments, such as cother one, benzene, khalene, al Alkane, aldehyde, phenol, and other volatile gases are mainly used in chemical, machinery, printing, rubber, furniture, electromechanical, marine, automobile, petroleum and other industries.

The activated carbon bed treats VOC organic waste gas, with mature technology, stable operation and good treatment effect. At the same time, according to the characteristics of the exhaust gas emitted in different production processes, such as the temperature of the exhaust gas, whether it contains oil mist, dust and other related parameters, pretreatment devices such as coolers and primary filters can be built or added at the inlet end of the activated carbon bed. It protects the activated carbon absorption section and ensures that the activated ate operator carbon in be a high-efficiency state. The activated carbon absorption and absorption efficiency is high, and the purification capacity meets the national environmental protection requirements.

Custom designed to meet application requirements,

Flow ranges from 50 cfm to 500,000 cfm

Modular system

Flexible container options such as stainless steel, PP polypropylene

Single or two stage system

Vertical/horizontal design

Reduced footprint due to efficient media

Low maintenance

Rugged Design

Low life cycle cost

Energy efficient

Easy to install and operate

Optional blowe

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |