- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 14 Author: China xicheng Publish Time: 2021-04-17 Origin: China xicheng

Most university laboratories emit exhaust gas directly outside, lacking effective control measures. There are many components of laboratory exhaust gas, and direct emissions pollute the environment and harm the health of teachers and students. The new environmental regulations require that laboratory exhaust gas be effectively collected and treated before discharge. The following Dongfeng Environmental Protection will introduce you to the characteristics and treatment process of laboratory exhaust gas.

1. There are many types and complex ingredients, such as hydrogen chloride, hydrogen bromide, nitric acid, chloric acid, sulfuric acid, dichloromethane, ethyl acetate, toluene, acrylic acid, acetic acid, methanol, ethanol, etc.

2. Unstable emissions. When the exhaust system is turned on, because the opening time of the ventilation system in each laboratory is not fixed, and the duration of use is also different, the rate of exhaust gas emission is unstable, and it is discharged intermittently.

3. Large air volume and low concentration. Exhaust gas treatment is mainly collected by open-air collecting hoods or semi-open fume hoods. When the wind speed of air-containing hoods and fume hoods increases, the air volume of the exhaust gas collection system is more significant.

4. The source is scattered, showing three-dimensional pollution. The laboratory is a multi-story building located on multiple floors. The exhaust gas emission sources are relatively scattered. In the three-dimensional form of corruption, the design of the gas collection tube has caused some difficulties.

1. Wet waste gas treatment

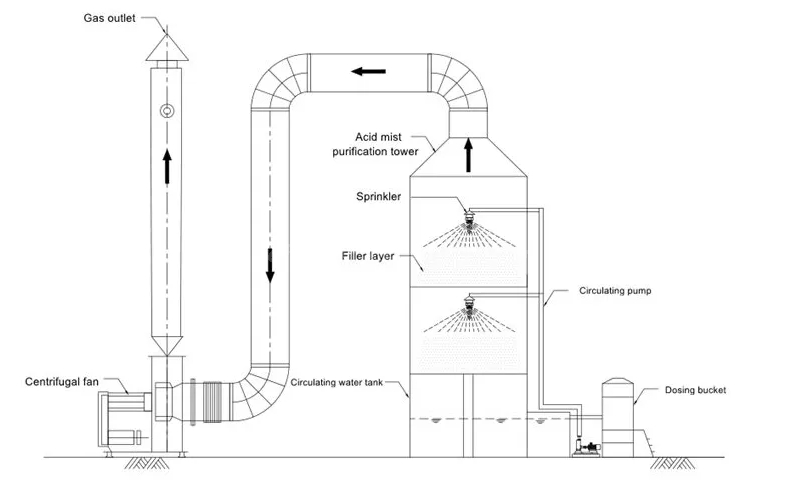

Wet waste gas treatment adopts acid mist scrubber for waste gas treatment, which is suitable for purifying hydrogen chloride gas (HCl), hydrogen fluoride gas (HF), ammonia (NH3), sulfuric acid mist (H2S04), chromic acid mist (Cr03), hydrogen cyanide Acid gas (HCN), hydrogen sulfide gas (H2S), low-fluidity NOx waste gas and other water-soluble gases, with good purification effect, compact structure, small footprint, good corrosion resistance, good aging resistance, installation, transportation, and maintenance Convenient management, relatively simple equipment structure, low one-time investment, etc., so it is widely used in the treatment of acid and alkali waste gas.

The acid mist scrubber is suitable for installation on the roof of high-rise buildings. The working principle is that the acid mist exhaust gas is forced into the absorption tower by the fan and passes through the inlet spray and the middle packing layer. The acid mist and the alkaline substances in the tower undergo a neutralization reaction. After purification, The gas is then deliquored and then discharged at high altitudes.

2. Dry waste gas treatment

Dry waste gas treatment is a process in which the unbalanced molecular attraction or chemical bonding force on the surface of the solvent is used to adsorb specific organic components in the gas on the surface of the solid solvent when the waste gas is in contact with the porous solid solvent. The advantages of this method are simple equipment, convenient operation, and easy realization of automatic control. However, due to the different physical and chemical properties of adsorbents, they have strong pertinence. Therefore, to treat exhaust gas components, it is necessary to configure adsorbents with other properties to achieve a good exhaust gas purification effect. Besides, if the exhaust gas concentration is too high or through adsorption, if the agent's time is short, the exhaust gas purification effect will be unsatisfactory. At the same time, a fan must be added to ensure the average wind speed of the ventilation system. Finally, the adsorbent needs to be replaced or regenerated regularly to ensure the regular operation of the absorption device. Therefore, the method needs to invest a certain amount of praise and workforce in practical applications. It is primarily suitable for treating some organic waste gas with stable waste gas composition and low concentration.

The exhaust gas from the laboratory contains inorganic environmental pollutants such as hydrogen chloride and hydrogen bromide and methanol, ethanol, and other volatile and organic substances. Two types of contaminants should be considered in the process design. Because the water solubility of some inorganic substances can be better, the treatment structure process for these inorganic substances is relatively simple, mainly using water for absorption method, lye absorption method, and other functions.

Currently, widely used technologies include condensation, absorption, adsorption, photocatalysis, biological methods, low-temperature plasma, combustion, and other processes. Each technology has its advantages and disadvantages and its application.

The condensation method is suitable for the treatment of small air volume and high concentration waste gas and is widely used in the recovery of solvents;

The absorption method is suitable for the treatment of organic matter with good water solubility and is often used as a waste gas pretreatment process;

The combustion method is suitable for high-concentration, high-calorific value, stable emission, and halogen-free organic waste gas;

Biological method and photocatalysis are suitable for simple deodorization of organic waste gas and are often used for waste gas treatment in sewage stations;

The adsorption method is suitable for the adsorption of most organic substances, has good universality, and is ideal for treating low-concentration, intermittently discharged organic waste gas.

Each technology has its emission control technology, valuable objects, and shortcomings. No technology can treat all exhaust gas pollutants. Therefore, the exhaust gas considered in the design of this method is a combination of more conventional exhaust gas treatment technologies, which have weaknesses.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |