- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 76 Author: XICHENG EP LTD Publish Time: 2025-01-06 Origin: XICHENG EP LTD

PP plastic sheet refers to a plastic sheet made of polypropylene (PP) as the main raw material. It is a lightweight, chemically resistant, non-toxic and environmentally friendly thermoplastic material, widely used in chemical, construction, electronics, food, medicine and other industries.

What is PP plastic? PP plastic Polypropylene is a polymer, a product of propylene polymerization. The chemical formula of PP plastic is (C3H6)n. It is a thermoplastic plastic with a certain degree of transparency. It is colorless, odorless, tasteless and non-toxic.

PP plastic beads

During the production process, PP plastic is often mixed with colored plastic beads and safety additives to create hardness, durability or flexibility and more eye-catching colors in the finished product.

PP plastic sheet is a technical plastic sheet made of PP plastic granules with various functional additives to increase hardness, chemical resistance, heat resistance and wear resistance. PP sheet is produced through extrusion, calendering, cooling, cutting and other processes.

PP plastics are used in many daily necessities, such as bottles, drinking water jugs, milk jugs, detergents, food storage boxes, baskets, buckets, water barrels, plastic cutting boards, children's toys, baby bottles... PP engineering plastic sheets. Used in making chemical tanks, electroplating, making industrial plastic cutting boards, interior decoration, advertising signs, chemical plant waste gas treatment equipment, pollution treatment and other industrial fields...

Users can choose the appropriate PP sheet thickness according to the purpose of use. The thickness of the PP plastic sheet currently produced ranges from 3mm -> 20mm.

Some common PP sheet thicknesses:

20mm PP plastic sheet

28mm PP plastic sheet

15mm PP plastic sheet

12mm PP plastic sheet

10mm PP plastic sheet

8mm PP plastic sheet

5mm PP plastic sheet

PP plastic sheets are not as flexible as PE plastics, have better transparency than PE, are lighter than water, and have a harder surface than HDPE plastics (HDPE is high-density PE plastic).

PP sheets can withstand higher temperatures than PVC (PP plastic can withstand temperatures up to 100°C, PP welding temperature is about 140°C, while PVC sheets can only withstand up to 60°C)

Excellent corrosion resistance and good chemical stability.

White PP plastic sheet has uniform thickness, smooth surface, high mechanical strength (withstands strong impact without deformation), is not affected by corrosive chemicals or harsh environment, is water-resistant, and is insulated

In terms of mechanical properties, PP plastic is superior to PE plastic, so it has strong applications in more industrial fields.

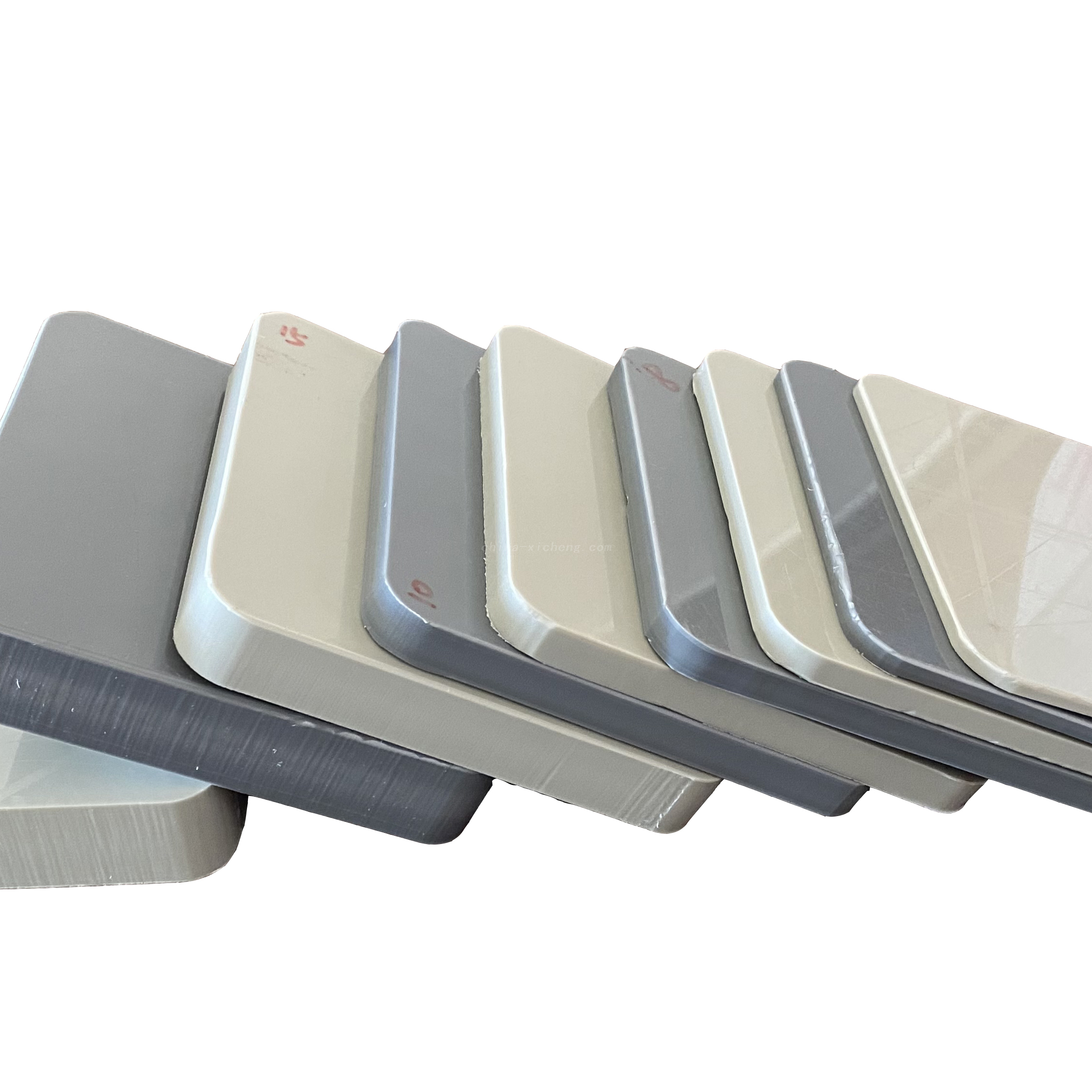

White, gray, cream PP plastic sheets

| Technical indicators | scope |

| tensile strength | 3050–3495 (N/cm2) |

| Elongation at break | 50 – 65 (%) |

| Bending strength | 41.2 – 49.8 (MPa) |

| Dimensional change in 6 hours at 55 °C | 0.01 – 0.1 (%) |

| Vicat temperature | 77(℃) |

| Standard size | 1000×2000; 1220×2440 (mm) |

| thickness | 3, 5, 8, 10, 12, ... 25, 30 (mm) |

| color | White, creamy yellow, grey or as required |

| Production Unit | FALU thermal conductive material |

Manufacturing of tanks for storing chemicals and electroplating

Such as chrome plating, copper liquid bleaching -> PP plastic has better heat resistance than PVC, but PVC's antioxidant ability is still better than PP.

PP plastic sheets as ventilation system

In some working environments where the temperature is relatively high and the straw cross-section is not too large, the unit chooses PP for processing.

The wet scrubber system is made of PP plastic

Cutting boards and molds for making food and medicine

PP Industrial Plastic Cutting Boards in Food Processing Industry

PP plastic sheets are made of PP plastic granules with safe additives, which have anti-wear properties, are resistant to chemicals, and can withstand temperatures up to 100°C. On the other hand, PP sheets can withstand higher temperatures than PVC sheets, are lighter in weight, and can therefore be applied in more specialized environments, and the product does not contain toxins and is safe for health, so it can be used in industrial applications. . Chemical, electroplating, food, pharmaceutical.

PP plastic is colorless, odorless, tasteless and safe for health, so it is widely used in the food processing industry and furniture manufacturing.

In daily life, you can easily come across products made of PP plastic, such as: baby bottles, children's toys, plastic food containers, plastic drinking water bottles...

When burning, PP emits a bright light blue flame, flows flexibly, and has a burning odor similar to that of rubber.

For products made of PP plastic, there will be a triangle symbol with the number 5, as shown below

When buying PP sheets, you need to determine your usage scenario first. PP sheets cannot be used in high temperature and sub-zero environments.

There are many types of PP sheets, and the raw materials of different types are different.

PP sheets include flame-retardant PP sheets and ordinary PP sheets. Flame-retardant PP has a certain fireproof ability and can organize the spread of flames to the maximum extent.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |