- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 12 Author: XICHENG EP LTD Publish Time: 2024-06-14 Origin: XICHENG EP LTD

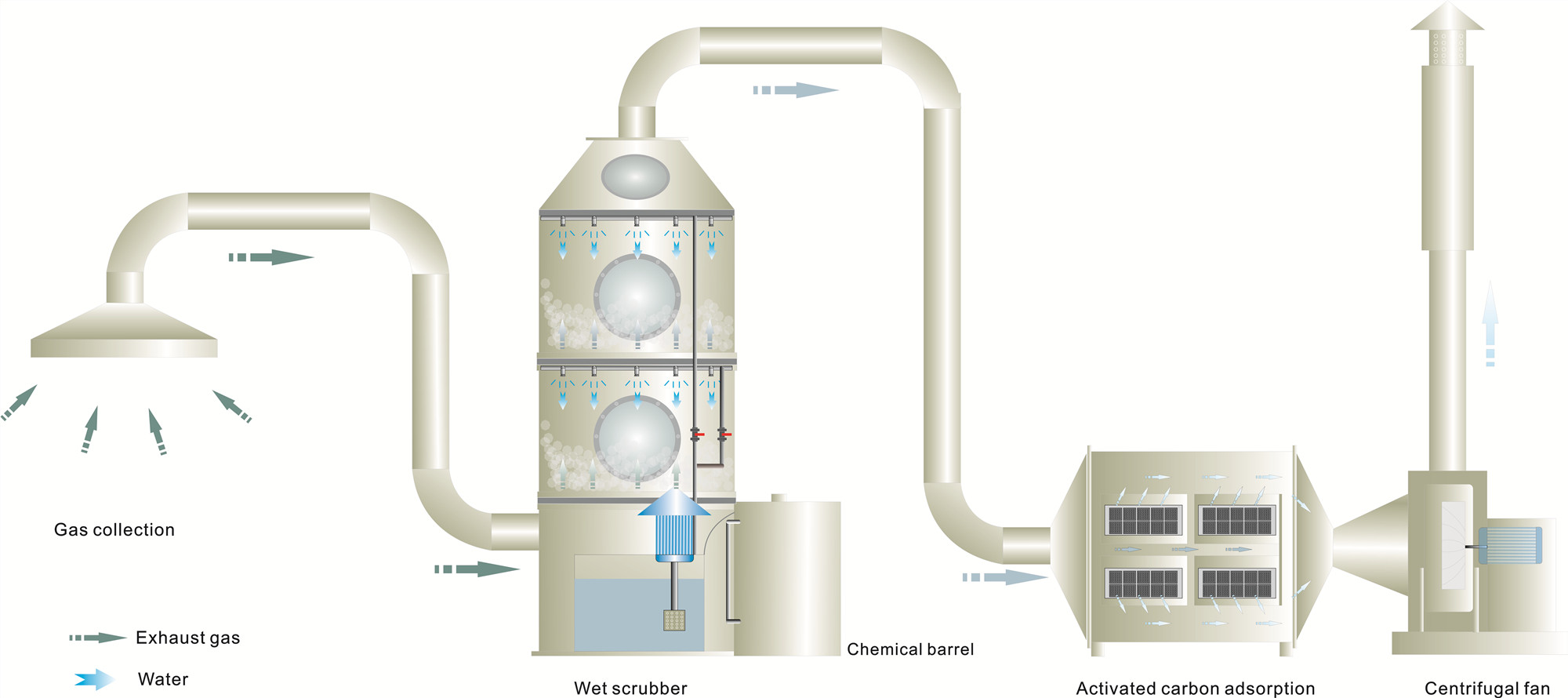

Fume scrubber, also known as a gas scrubber or wet scrubber, is a device used to remove pollutants from industrial exhaust streams. The primary function of a fume scrubber is to capture and neutralize harmful gases and particulate matter before they are released into the atmosphere. Here’s a detailed explanation of how it works:

Basic Principles

Contacting Pollutant-Laden Gas with Liquid:

The core principle of a fume scrubber is to bring the polluted gas stream into contact with a scrubbing liquid (often water or a chemical solution). This interaction helps to transfer pollutants from the gas phase to the liquid phase.

Absorption and Reaction:

Pollutants are either absorbed into the liquid or undergo a chemical reaction with the scrubbing liquid. For example, acidic gases like sulfur dioxide (SO₂) can react with alkaline scrubbing solutions to form neutral salts.

Scrubbing Liquid:

The liquid used can be water for particulate removal or a specific chemical solution for gas absorption. The choice depends on the nature of the pollutants.

Packing Material:

Many scrubbers contain packing materials such as Raschig rings, Berl saddles, or structured packings. These materials increase the surface area for contact between the gas and the liquid.

Gas Inlet and Distribution System:

The polluted gas enters the scrubber through an inlet and is distributed evenly to maximize contact with the scrubbing liquid.

Liquid Distribution System:

The scrubbing liquid is sprayed or distributed over the packing material, creating a thin film or droplets for efficient gas-liquid interaction.

Mist Eliminator:

After the gas has been scrubbed, it passes through a mist eliminator to remove entrained liquid droplets, ensuring that only clean gas is emitted.

Spray Tower Scrubbers:

These use a series of spray nozzles to disperse the scrubbing liquid into the gas stream. The droplets capture pollutants as they fall through the gas.

Packed Bed Scrubbers:

These use packing materials to provide a large surface area for gas-liquid contact. The gas flows up through the packed bed, while the liquid flows down.

Venturi Scrubbers:

These use a Venturi-shaped section to accelerate the gas and create a pressure drop, which enhances mixing and contact between the gas and liquid. The high-velocity gas shears the liquid into fine droplets, increasing the interaction surface area.

Plate Tower Scrubbers:

These contain perforated plates or trays through which the gas and liquid pass. The gas bubbles through the liquid on each plate, promoting contact.

Operation Process

Gas Entry:

Polluted gas enters the scrubber and is evenly distributed.

Gas-Liquid Contact:

The gas comes into contact with the scrubbing liquid, where pollutants are absorbed or chemically neutralized.

Gas Cleaning:

The scrubbed gas moves upward, passing through packing material or spray zones, allowing maximum contact with the liquid.

Mist Elimination:

Clean gas passes through a mist eliminator to remove any remaining liquid droplets.

Discharge:

Clean gas is released into the atmosphere, and the polluted liquid is collected for disposal or treatment.

Efficiency and Applications

Efficiency: The efficiency of a fume scrubber depends on the design, type of pollutants, and operating conditions. Proper design and maintenance can achieve high removal efficiencies for various pollutants.

Applications: Fume scrubbers are used in various industries, including chemical manufacturing, metal processing, power generation, and waste treatment, to control emissions of harmful gases and particulates.

By utilizing these principles and components, fume scrubbers effectively reduce air pollution and help industries comply with environmental regulations.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |