- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

XC-1

XICHENG

Advanced Solutions for Clean Energy Generation

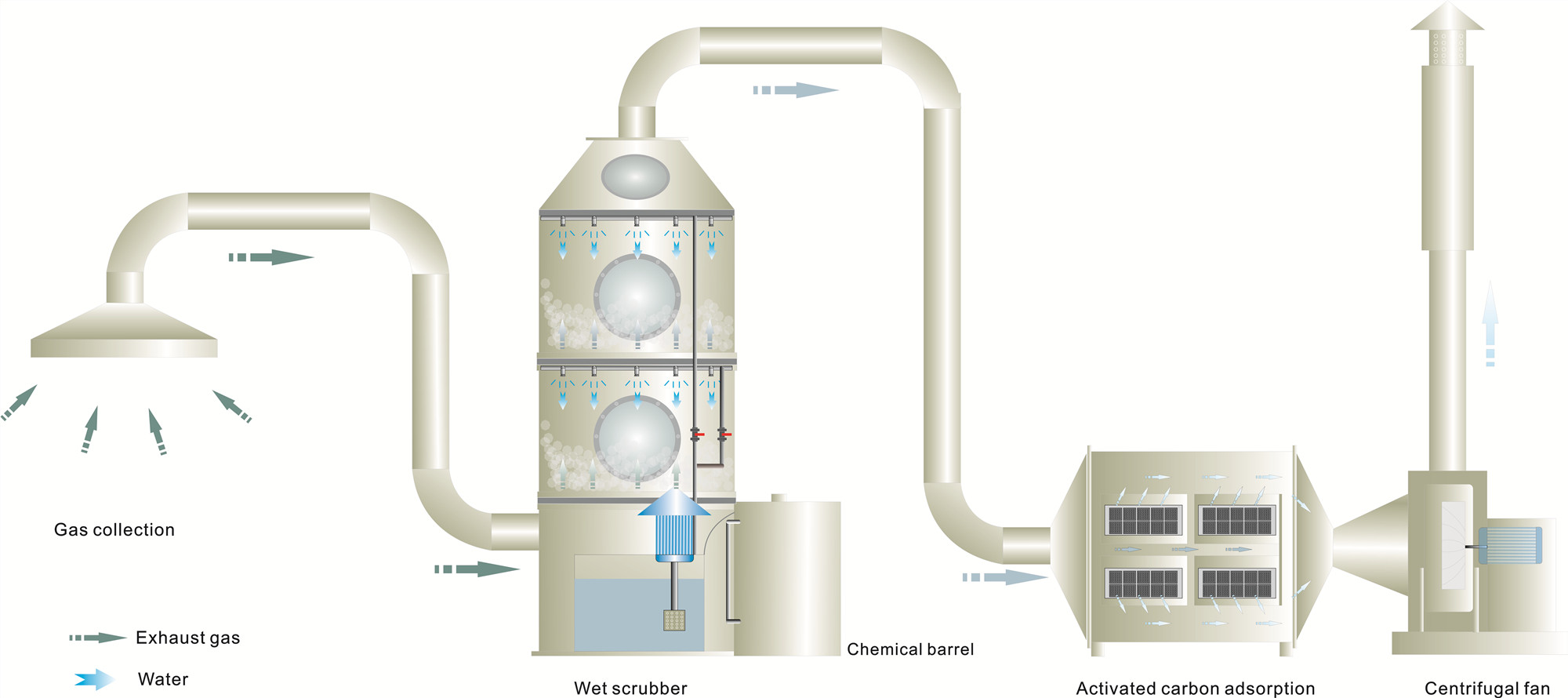

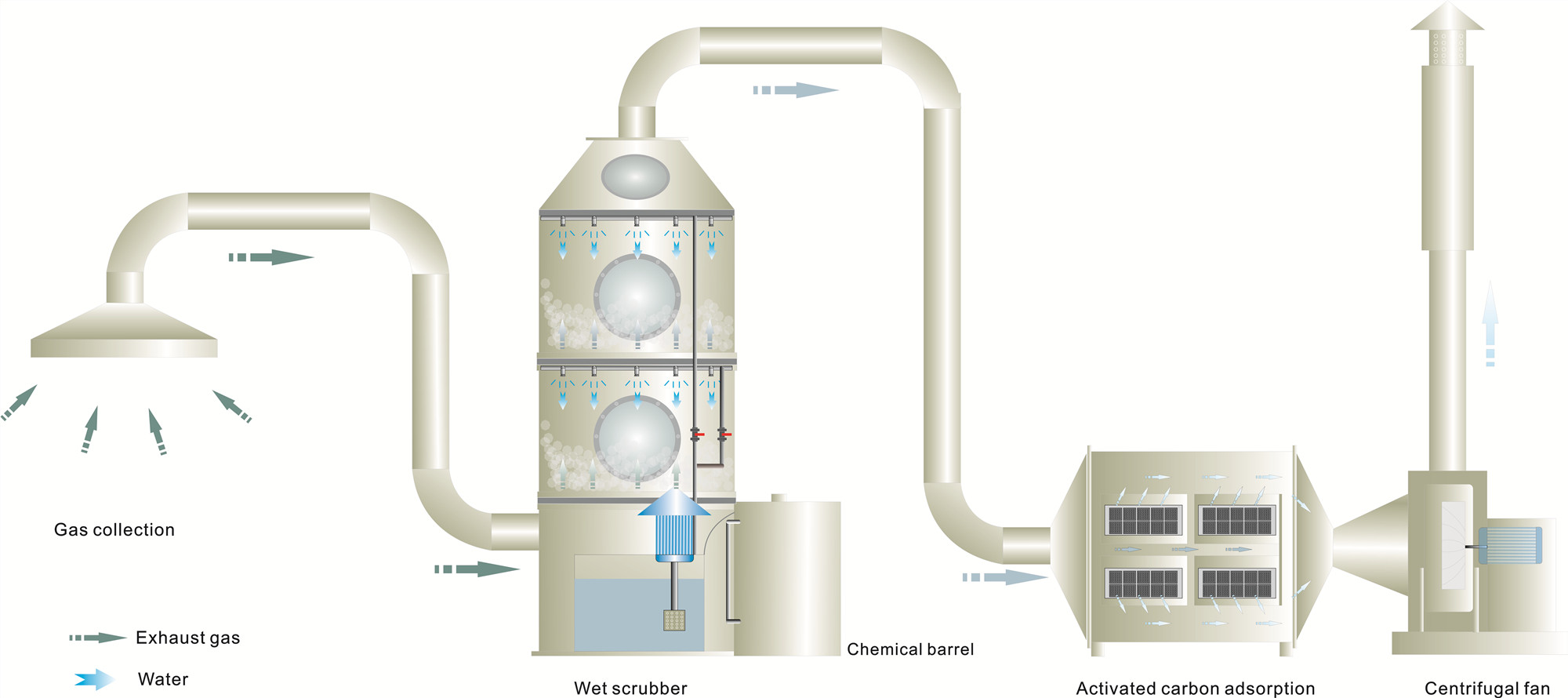

Waste-to-Energy (WTE) plants convert municipal solid waste (MSW) into electricity/heat but produce toxic flue gases (HCl, SO₂, NOx, dioxins, heavy metals). Effective flue gas treatment is critical to meet environmental regulations (EU IED, US EPA, China GB 18485). Below are key technologies and processes used globally.

| Pollutant | Concentration Range | Source | Health/Environmental Risk |

|---|---|---|---|

| Dust/Particulates | 1,000–5,000 mg/Nm³ | Incomplete combustion | Respiratory diseases |

| HCl | 200–1,000 mg/Nm³ | PVC, plastics | Corrosion, acid rain |

| SO₂ | 50–500 mg/Nm³ | Rubber, textiles | Acid rain, lung damage |

| NOx | 100–400 mg/Nm³ | High-temperature combustion | Smog, ozone depletion |

| Dioxins/Furans | 0.1–10 ng TEQ/Nm³ | Chlorinated waste | Carcinogenic, bioaccumulative |

| Hg/Cd/Pb | 0.01–5 mg/Nm³ | Batteries, electronics | Neurotoxicity, soil contamination |

Electrostatic Precipitator (ESP)

Removes 99% of fly ash (efficiency: <10 mg/Nm³).

Operating Temp: 200–300°C (before quenching).

Fabric Filter (Baghouse)

Used with activated carbon injection for dioxin/heavy metal adsorption.

Material: PTFE-coated fiberglass (resists acid gases).

| Technology | Reagents | Efficiency | Pros & Cons |

|---|---|---|---|

| Wet Scrubber | NaOH/Ca(OH)₂ slurry | HCl: >99% | ✅ High efficiency ❌ Wastewater |

| Semi-Dry Scrubber | Lime slurry + spray drying | SO₂: 90% | ✅ No wastewater ❌ Higher reagent use |

| Dry Scrubbing | NaHCO₃ powder | HCl/SO₂: 85% | ✅ Compact design ❌ Frequent replacement |

Selective Catalytic Reduction (SCR)

Uses NH₃/urea + catalyst (V₂O₅-WO₃/TiO₂) at 180–400°C.

Efficiency: >90% NOx removal.

Selective Non-Catalytic Reduction (SNCR)

Injects ammonia at 900–1,100°C (less efficient: 30–70%).

Activated Carbon Injection (ACI)

Powdered AC adsorbs dioxins (99%) + Hg (90%).

Dosage: 50–200 mg/Nm³.

Catalytic Filters (DeNOx + DeDioxin)

Combined SCR + dioxin destruction (e.g., Haldor Topsoe’s SNOX).

Wet ESP or HEPA Filter for sub-micron particles.

Continuous Emission Monitoring (CEMS) for real-time compliance.

| Region | Standard | Emission Limits (mg/Nm³) |

|---|---|---|

| EU | IED (2010/75/EU) | HCl: 10, SO₂: 50, NOx: 200, Dust: 10 |

| USA | EPA MACT | HCl: 25, SO₂: 30, NOx: 150, Hg: 0.005 |

| China | GB 18485-2014 | HCl: 60, SO₂: 100, NOx: 300, Dioxins: 0.1 ng TEQ |

Plasma-Assisted Catalysis (Break down dioxins at low temps).

AI-Optimized Reagent Dosing (Reduces chemical consumption by 20%).

Carbon Capture (Amine scrubbing for CO₂ from WTE flue gas).

Modern WTE plants integrate multi-stage flue gas treatment to achieve near-zero emissions. Wet scrubbing + SCR + ACI is the gold standard, while semi-dry systems dominate in space-constrained areas. Future trends focus on energy recovery and AI-driven optimization.

Advanced Solutions for Clean Energy Generation

Waste-to-Energy (WTE) plants convert municipal solid waste (MSW) into electricity/heat but produce toxic flue gases (HCl, SO₂, NOx, dioxins, heavy metals). Effective flue gas treatment is critical to meet environmental regulations (EU IED, US EPA, China GB 18485). Below are key technologies and processes used globally.

| Pollutant | Concentration Range | Source | Health/Environmental Risk |

|---|---|---|---|

| Dust/Particulates | 1,000–5,000 mg/Nm³ | Incomplete combustion | Respiratory diseases |

| HCl | 200–1,000 mg/Nm³ | PVC, plastics | Corrosion, acid rain |

| SO₂ | 50–500 mg/Nm³ | Rubber, textiles | Acid rain, lung damage |

| NOx | 100–400 mg/Nm³ | High-temperature combustion | Smog, ozone depletion |

| Dioxins/Furans | 0.1–10 ng TEQ/Nm³ | Chlorinated waste | Carcinogenic, bioaccumulative |

| Hg/Cd/Pb | 0.01–5 mg/Nm³ | Batteries, electronics | Neurotoxicity, soil contamination |

Electrostatic Precipitator (ESP)

Removes 99% of fly ash (efficiency: <10 mg/Nm³).

Operating Temp: 200–300°C (before quenching).

Fabric Filter (Baghouse)

Used with activated carbon injection for dioxin/heavy metal adsorption.

Material: PTFE-coated fiberglass (resists acid gases).

| Technology | Reagents | Efficiency | Pros & Cons |

|---|---|---|---|

| Wet Scrubber | NaOH/Ca(OH)₂ slurry | HCl: >99% | ✅ High efficiency ❌ Wastewater |

| Semi-Dry Scrubber | Lime slurry + spray drying | SO₂: 90% | ✅ No wastewater ❌ Higher reagent use |

| Dry Scrubbing | NaHCO₃ powder | HCl/SO₂: 85% | ✅ Compact design ❌ Frequent replacement |

Selective Catalytic Reduction (SCR)

Uses NH₃/urea + catalyst (V₂O₅-WO₃/TiO₂) at 180–400°C.

Efficiency: >90% NOx removal.

Selective Non-Catalytic Reduction (SNCR)

Injects ammonia at 900–1,100°C (less efficient: 30–70%).

Activated Carbon Injection (ACI)

Powdered AC adsorbs dioxins (99%) + Hg (90%).

Dosage: 50–200 mg/Nm³.

Catalytic Filters (DeNOx + DeDioxin)

Combined SCR + dioxin destruction (e.g., Haldor Topsoe’s SNOX).

Wet ESP or HEPA Filter for sub-micron particles.

Continuous Emission Monitoring (CEMS) for real-time compliance.

| Region | Standard | Emission Limits (mg/Nm³) |

|---|---|---|

| EU | IED (2010/75/EU) | HCl: 10, SO₂: 50, NOx: 200, Dust: 10 |

| USA | EPA MACT | HCl: 25, SO₂: 30, NOx: 150, Hg: 0.005 |

| China | GB 18485-2014 | HCl: 60, SO₂: 100, NOx: 300, Dioxins: 0.1 ng TEQ |

Plasma-Assisted Catalysis (Break down dioxins at low temps).

AI-Optimized Reagent Dosing (Reduces chemical consumption by 20%).

Carbon Capture (Amine scrubbing for CO₂ from WTE flue gas).

Modern WTE plants integrate multi-stage flue gas treatment to achieve near-zero emissions. Wet scrubbing + SCR + ACI is the gold standard, while semi-dry systems dominate in space-constrained areas. Future trends focus on energy recovery and AI-driven optimization.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |