- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 18 Author: Xicheng EP LTD Publish Time: 2023-09-15 Origin: Xicheng EP LTD

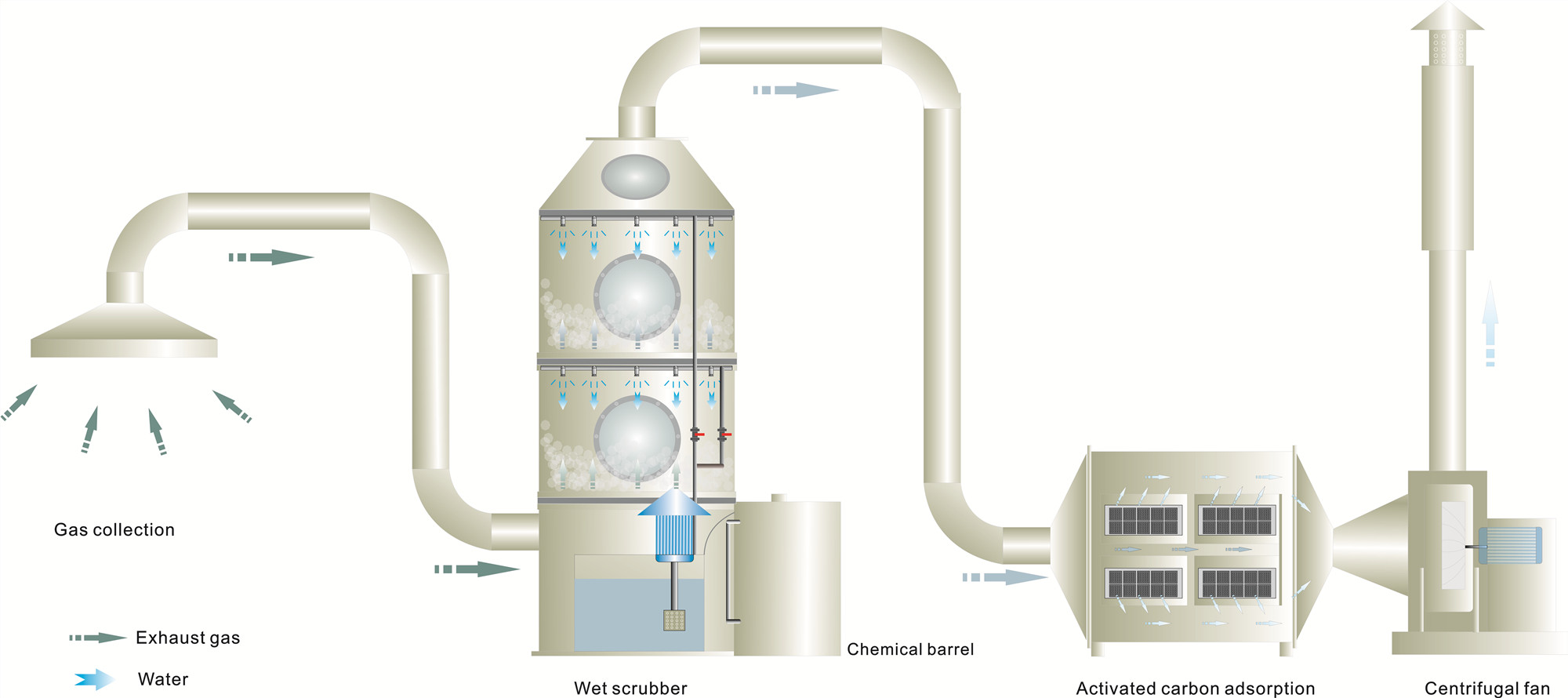

Designing an ethylene oxide scrubber involves creating a system that can effectively remove ethylene oxide (EtO) gas from the air, typically in industrial or medical settings. Ethylene oxide is a hazardous and carcinogenic gas used for sterilization and as a chemical intermediate.

Understand Ethylene Oxide Properties:

Understand the properties of ethylene oxide, such as its chemical composition, concentration in the air, and temperature and pressure conditions under which it is present.

Regulations and Safety:

Comply with all local, state, and federal regulations regarding the handling and removal of ethylene oxide. Ensure safety measures for personnel and the environment.

Scrubber Type:

Select the appropriate type of scrubber. Common types for removing EtO include adsorption systems, chemical scrubbers, and catalytic scrubbers.

Adsorption Systems:

For adsorption systems, select suitable adsorbents like activated carbon or zeolite, which can adsorb ethylene oxide molecules from the air.

Chemical Scrubbers:

In chemical scrubbers, EtO is reacted with a chemical absorbent, typically an alkaline solution like sodium hydroxide. Ensure proper containment and disposal of the resultant waste.

Catalytic Scrubbers:

Catalytic scrubbers use a catalyst to break down EtO into less harmful compounds. Select an appropriate catalyst and design the reactor accordingly.

Flow Rate and Residence Time:

Calculate the required airflow rate and residence time to effectively remove EtO. This depends on the concentration of EtO in the incoming air and the desired removal efficiency.

Temperature and Pressure:

Consider the temperature and pressure conditions at which the scrubber will operate. EtO removal efficiency can vary with these factors.

Monitoring and Control:

Implement a monitoring and control system to ensure the scrubber operates within the desired parameters. This may include sensors to measure EtO concentration and control mechanisms to adjust the scrubber's operation.

Ventilation:

Ensure proper ventilation in the area to maintain a safe working environment. This can include exhaust fans and ductwork.

Waste Disposal:

Develop a plan for the safe disposal of the captured ethylene oxide or the waste generated from the scrubbing process. This may involve contacting hazardous waste disposal services.

Maintenance:

Establish a regular maintenance schedule for the scrubber system to ensure its continued effectiveness and safety.

Training:

Train personnel on the proper operation, maintenance, and safety procedures related to the ethylene oxide scrubber.

Emergency Procedures:

Develop emergency response procedures in case of equipment failure or other unexpected incidents.

Documentation:

Maintain detailed records of the scrubber's operation, maintenance, and monitoring results to demonstrate compliance with regulations.

Testing and Validation:

Periodically test and validate the scrubber's performance to ensure it continues to meet the required standards for EtO removal.

It's crucial to involve experienced engineers and consultants with expertise in air pollution control and hazardous materials handling when designing an ethylene oxide scrubber, as the process can be complex and must prioritize safety and compliance. Additionally, consult with relevant regulatory agencies to ensure full compliance with all applicable regulations.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |