- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 14 Author: Xicheng EP LTD Publish Time: 2022-08-26 Origin: Xicheng EP LTD

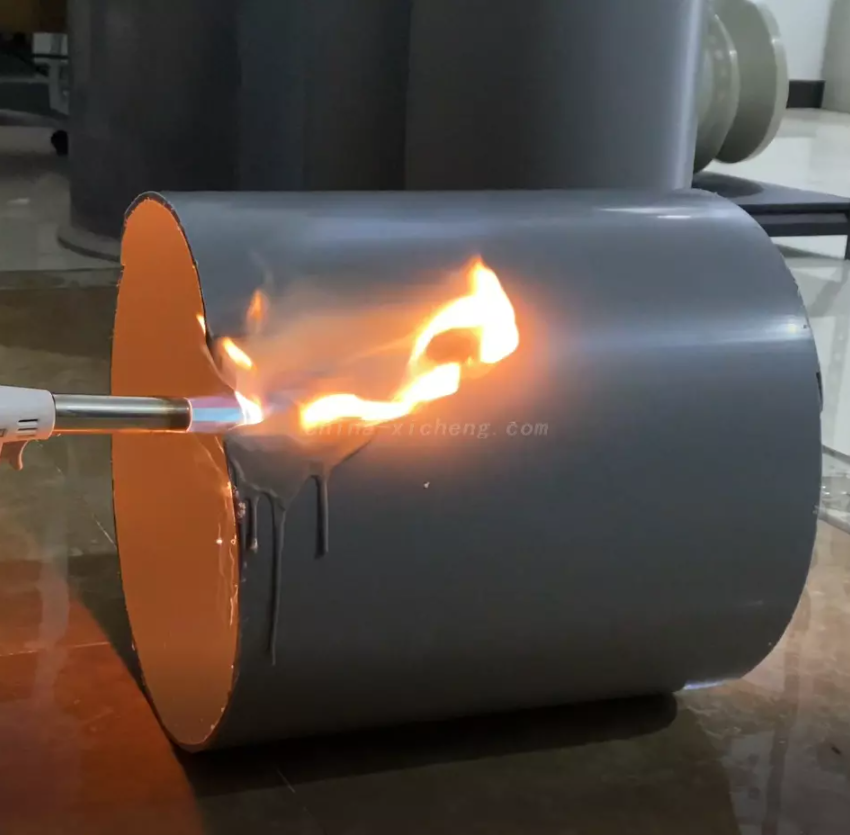

The flame retardant grade of plastic decreases from V-0, V-1, V-2 to HB:

V-0: The flame was extinguished within 30 seconds after two 10-second burn tests on the sample. No burning objects should fall.

V-1: After the sample was subjected to two 10-second burn tests, the flame was extinguished within 60 seconds. No burning objects should fall.

V-2: The flame was extinguished within 60 seconds after two 10-second burn tests on the sample. Combustibles may fall.

HB: The lowest flame retardant rating in UL94 and CSA C22.2 No 0.17 standards.

It is required that for samples 3 to 13 mm thick, the burning rate is less than 40 mm per minute; for samples less than 3 mm thick, the burning rate is less than 70 mm per minute; or it is extinguished before the 100 mm mark.

American Standard and Test Methods for Flame Retardant Materials

American flame retardant material standard is ANSI/UL-94-1985 standard

There are five types of UL94 tests:

B-level horizontal combustion test

Vertical combustion test of 94V-0, 94V-1, 94V-2 grades

94 Vertical Fire Test for Class 5-V

Flame spread index test with radiant panels (measured according to ASTM E 162, not introduced here)

94VTM-0, 94VTM-1, 94VTM-2 vertical combustion test (VTM refers to extremely thin materials, which will not be introduced here)

94HB level horizontal combustion test method:

Test sample: use a small strip sample with a length of 127mm, a width of 12.7mm, a maximum thickness of 12.7mm and a minimum thickness of 3.05mm.

Test conditions: in a non-ventilated test box.

Evaluation method: For materials rated as 94HB, when the thickness of the sample is 12.7mm, the burning speed on the gauge length of 76.2mm is not more than 38.1mm/min, or when the thickness of the sample is less than 3.05mm, the burning speed is not more than 38.1mm/min. min or before reaching the 102mm reticle, the burning must be stopped.

Vertical combustion test method for 94V-0, 94V-1, 94V-2 grades:

Test sample: The small strip sample used for this test is 127mm long, 12.7mm wide and 12.7mm thick.

Test conditions: in a non-ventilated test box.

Evaluation method: The upper end of the sample (6.4mm place) is clamped with the clamp on the bracket, and the longitudinal axis of the sample is kept vertical. The lower end of the sample is 9.5mm away from the lamp nozzle and 305mm away from the surface of the dry absorbent cotton. Ignite and adjust the Bunsen burner to produce a 19mm high blue flame, place the Bunsen burner flame at the lower end of the sample, ignite for 10s, then remove the flame (at least 152mm away from the sample), and note that the sample has flames Burn time. If the flame of the sample is extinguished within 30s after the flame is removed, the Bunsen burner must be moved under the sample again, the sample must be re-ignited for 10s, and then the flame of the Bunsen burner must be removed again, and the flaming combustion of the sample must be recorded. and afterburning time for flameless combustion. If the sample droplets are in the smoke, let them fall on the absorbent cotton 305mm under the sample to see if it ignites the absorbent cotton. If absorbent cotton catches fire, this factor should be considered in the rating.

| | N0.34 Zhenxing Road (Shengtaian Heavy Industrial Park B), Loucun, Guangming New Dist, Shenzhen, Guangdong, China |

| | +86 18028775826 |

| | Leyte@china-xicheng.com |